Highclean ImmersibleTransducers make it easy for you to add ultrasonic cleaning and degreasing efficiency without the investment required for self-contained units — because you use your own tanks.

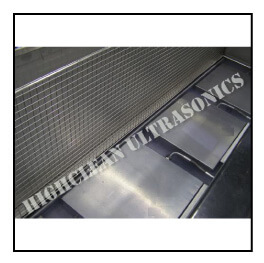

Economically designed for tough cleaning applications, the Immersibles are ideal for the removal of oils, ground-in buffing and polishing compounds and a wide variety of other hard-to-remove contaminates. Piezo ceramic transducers are welded into water-tight, stainless steel submersible units. These units are equipped with mounting hooks and plumbed to your specifications. The powerful and effective scrubbing action of the exclusive piezo ceramics ultrasonic transducers reaches even the smallest of crevices and blind holes.

Immersible transducers, also known as submersible transducers or submersible ultrasonic transducers, are a type of ultrasonic cleaning component that can be submerged directly into a liquid for cleaning purposes. Unlike traditional ultrasonic cleaners that have a fixed tank and built-in transducers, immersible transducers offer greater flexibility in terms of their placement and use.

Here’s how immersible transducers work:

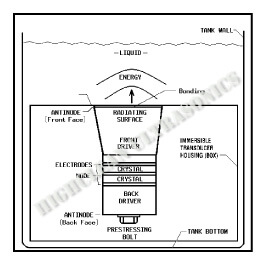

Construction: Immersible transducers are typically made of a piezoelectric material, such as ceramic or quartz, which converts electrical energy into mechanical vibrations. These transducers are enclosed in a protective housing that is designed to be submerged in a liquid.

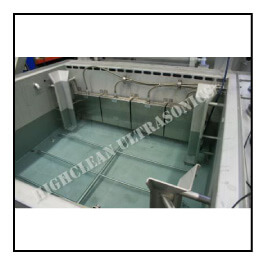

Mounting: Immersible transducers are usually mounted externally onto the side or bottom of a cleaning tank or vessel. They can be attached using brackets, clamps, or other securing mechanisms provided by the manufacturer. The transducer housing is designed to be waterproof to ensure safe operation when submerged.

Submersion: The cleaning tank or vessel is filled with a suitable cleaning solution, and the immersible transducers are submerged into the liquid. The liquid can be water-based or contain specialized cleaning agents depending on the specific cleaning requirements.

Ultrasonic Cleaning: Once the immersible transducers are powered on, they generate high-frequency sound waves (typically in the range of 20 to 40 kHz) that propagate through the cleaning solution. These sound waves create cavitation, which is the formation and collapse of microscopic bubbles.

Cavitation and Cleaning: The cavitation bubbles produced by the immersible transducers create intense scrubbing action when they collapse near the surfaces of the objects to be cleaned. This scrubbing effect helps to dislodge and remove dirt, grease, oils, and other contaminants from the objects.

Cleaning Time and Parameters: The cleaning time and other parameters, such as the temperature and power level, can be adjusted based on the specific cleaning requirements and the type of objects being cleaned. The manufacturer’s guidelines should be followed to ensure effective and safe cleaning.

Immersible transducers offer the advantage of flexibility in terms of their placement and use. They can be used in existing tanks or vessels, allowing for customization and adaptation to different cleaning setups. These transducers are commonly used in industrial settings where large-scale or customized cleaning systems are required.

It’s worth noting that immersible transducers are separate components that require a power supply and control system to operate. The power supply and control system can be separate or integrated into the cleaning setup, depending on the specific configuration and manufacturer.