OLD METHOD OF CLEANING

The current practice involves use of chlorinated solvents like TCE, PCE etc. that are the choice solvent used through the industries in their cleaning process. Aqueous ultrasonic cleaning system are very popular due to their good solvency, lower heat of evaporation, high or absence of flash point, non-corrosive nature, relative stability & compatibility with metals & glass. However all chlorinated solvents are hazardous to human health & environment.

Some chlorinated solvents are suspected to cause cancer (Carcinogenic) over prolong exposure. Being hazardous to health their usage has come under intense investigation from pollution control & health authorities & has already been banned by developed countries. This has lead to shift to alternative cleaning technology based on aqueous solvents.

Another factor driving the shift to aqueous ultrasonic cleaning system is the environmental hazard caused by chlorinated solvents due to their Ozone depleting property. Due to this they have been targets of strong Government regulations throughout the world. It may be not long before similar legislation is introduced in India to phase out their usage.

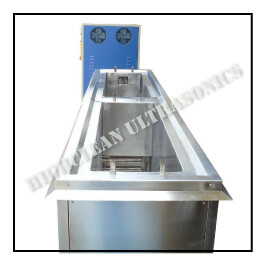

THE NEW METHOD

Aqueous ultrasonic cleaners are environmentally benign, technically feasible alternative to solvent cleaning. The medium used for cleaning is predominantly water compounded with Alkali, Surfactants, Water conditioners, Corrosion inhibitors, Foam stabilizers etc.

Aqueous ultrasonic cleaners in many cases have replaced solvents without sacrificing cleaning performance. However due to the nature of solvent used, successful implementation of aqueous ultrasonic cleaning system require a careful design effort necessitated due to the multistage operations involved like

While solvent based cleaning primarily rely on chemical properties of the solvent, whereas aqueous ultrasonic cleaning system rely on the mechanical properties like high-pressure spray, Ultrasonic agitation, dunking, etc. apart from the chemical properties of the aqueous medium.

1.Pre cleaning tank (Injection flood wash)

A very high-pressure spray of liquid is introduced within the process liquid to create a strong turbulence causing effective mass transfer between the chemical (detergent) and the contaminant (oil). Subsequently saponification and emulsification processes are carried out.

2. Ultrasonic Cleaning

Ultrasonic power is created by Piezo electric crystals suitably bonded and excited by a high frequency signal create an alternate pressure effect in the liquid which dislodges minute particles. This effect tears apart the solution and produce cavitational bubbles. When these bubbles collapse, during the compressional mode of the cycle, high pressure mechanical effects are created blasting away the solid soil from the surface. While Ultrasonic cavitations aids in the solvency of the oil and fat in the cleaning media and the cavitational power helps in dislodging the solid soil.

3.Rinsing

The carry over chemicals on the surface of the components are removed in the rinsing station .To achieve a quick dissolution of the carry over chemicals the water is heated. Many a time this process is done twice at different stations.

4.Drying Hot air blow

The components are dried in this station by a blast of hot air at around 100 deg.

Multi-stage ultrasonic cleaning refers to a cleaning process that involves multiple sequential stages or steps within an ultrasonic cleaning system. Each stage serves a specific purpose and contributes to achieving a thorough and effective cleaning outcome. These stages can be tailored based on the specific cleaning requirements and the type of objects being cleaned. Here are some common stages in a multi-stage ultrasonic cleaning process:

Pre-cleaning or Pre-rinsing:

- This stage is focused on removing heavy or bulk contaminants from the objects before they undergo the main ultrasonic cleaning process.

- It can involve rinsing the objects with water or a suitable cleaning solution to remove loose debris, dirt, or oils.

- Pre-cleaning helps to prevent the excessive buildup of contaminants in the subsequent stages and enhances the overall cleaning effectiveness.

Ultrasonic Cleaning:

- The primary stage in a multi-stage ultrasonic cleaning process is the ultrasonic cleaning stage itself.

- Objects are immersed in a cleaning solution or solvent-filled tank equipped with ultrasonic transducers.

- The transducers generate high-frequency sound waves that create cavitation bubbles in the cleaning solution, which dislodge and remove contaminants from the objects.

- The objects are subjected to the ultrasonic waves for a specific duration based on the cleaning requirements and the level of contamination.

- This stage is crucial for achieving a deep and thorough cleaning of the objects, particularly in hard-to-reach areas and intricate surfaces.

Rinsing:

- After the ultrasonic cleaning stage, the objects are rinsed to remove any residual cleaning solution or contaminants.

- This stage helps to ensure that no cleaning agents or remaining debris are left on the objects.

- Rinsing can be done using clean water or a rinsing agent specifically designed for the particular application.

- Multiple rinse cycles may be performed to ensure complete removal of contaminants and cleaning agents.

Drying:

- The final stage in a multi-stage ultrasonic cleaning process is drying the objects.

- Drying can be accomplished through various methods such as air drying, forced air drying, vacuum drying, or heat-assisted drying.

- The purpose of this stage is to remove any remaining moisture or solvent residue, ensuring the objects are completely dry before further handling or processing.

By incorporating multiple stages in the ultrasonic cleaning process, the cleaning efficiency and effectiveness can be enhanced. Each stage focuses on a specific aspect of cleaning and contributes to achieving the desired cleanliness level for the objects being processed. The number and order of stages can be customized based on the specific cleaning requirements and the nature of the objects being cleaned.