Being perfectly shaped and swift movement of our organization, we are instrumental in offering a qualitative range of Single Ultrasonic Vapor Degreasers that are designed for high performance with outstanding cleaning speed for large volume cleaning applications. This offered range is designed by our professionals in compliance with international quality standards. Our provided range is manufactured using the latest technology, innovative machines and the finest raw material. These find versatile applications for efficient cleaning of electronics, electrical, aircraft, and automotive parts.

Since our establishment, we have become the well-known manufacturer, exporter and supplier of a high quality array of Ultrasonic Vapor Degreaser. This is designed to offer dependable cleaning that involves pre-cleaning that is followed by cleaning with powerful ultrasonic agitation and lastly vapor condensation for removal of residual debris from deep crevices and blind holes. The offered degreaser is manufactured by utilizing high grade raw materials and advance technology by our skilled engineers. Apart from this, our product is tested on various parameters in order to ensure its sturdiness and quality. Clients can avail this degreaser from us in different specifications and at affordable prices.

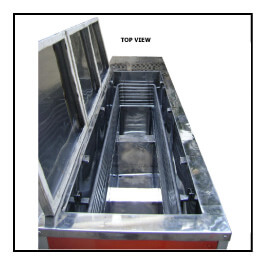

We put forward a broad range of Two Stage Ultrasonic Vapor Degreasing System that is manufactured in adherence with the set industry standards using advanced technology and optimum quality raw materials. In tune with international quality standard, we provide this system in various sizes and specifications, as per the requirement of our clients. Our quality controllers perform a series of test on various parameters, in order to ensure the quality of this system. This is used widely for cleaning of electronics, electrical, automotive, and aircraft parts. We offer these at leading industry rates to our patrons. Also this system is avail to our clients at pocket friendly rates.

Ultrasonic vapor degreasers are specialized machines used for precision cleaning of various components and parts in industries such as manufacturing, electronics, automotive, aerospace, and medical. These degreasers combine the power of ultrasonic cleaning and vapor degreasing techniques to effectively remove contaminants, oils, greases, and residues from the surfaces of the parts. Here’s how ultrasonic vapor degreasers typically work:

Vapor Degreasing: Ultrasonic vapor degreasers use a solvent-based cleaning process known as vapor degreasing. The machine contains a heated tank filled with a solvent, typically a chlorinated or fluorinated solvent such as trichloroethylene (TCE), perchloroethylene (PERC), or n-propyl bromide (nPB). The solvent creates a vapor layer above its surface due to the heating process.

Ultrasonic Cleaning: The ultrasonic vapor degreaser incorporates ultrasonic transducers in the tank. These transducers generate high-frequency sound waves, typically in the range of 20 to 40 kHz, which create cavitation in the solvent. The cavitation produces tiny bubbles that implode near the surfaces of the parts, providing intense scrubbing action and dislodging contaminants.

Cleaning Process: The parts to be cleaned are immersed in the vapor zone above the solvent. The vapor condenses on the cooler surfaces of the parts, dissolving and rinsing away contaminants. The ultrasonic energy enhances the cleaning process by effectively agitating the solvent and improving the penetration of the cleaning action into intricate geometries or hard-to-reach areas of the parts.

Gravity Draining: After the cleaning cycle, the parts are removed from the vapor zone, allowing the solvent to drain back into the tank due to gravity. This ensures that excess solvent is removed from the parts before further processing or drying.

Distillation and Filtration: To maintain the cleanliness and effectiveness of the solvent, ultrasonic vapor degreasers often include distillation and filtration systems. The distillation unit removes contaminants, oils, and other impurities from the solvent, making it reusable. Filtration systems can also be used to remove solid particles and debris from the solvent, further extending its lifespan.

Safety Considerations: As ultrasonic vapor degreasers use solvent-based cleaning, safety considerations are crucial. Adequate ventilation, proper handling and disposal of solvents, and compliance with safety regulations are essential to ensure the health and safety of operators and the environment. It’s important to consult local regulations and guidelines when using solvent-based cleaning systems.

Ultrasonic vapor degreasers offer several advantages, including excellent cleaning performance, efficient removal of contaminants, and the ability to clean complex-shaped parts with intricate geometries. They are particularly effective for removing oils and greases from precision parts, electronics, optical components, and medical devices. However, it’s important to consider factors such as the compatibility of the solvent with the parts being cleaned, the specific cleaning requirements, and safety considerations when selecting and using an ultrasonic vapor degreaser. Consulting with manufacturers or suppliers of industrial cleaning equipment can provide guidance on choosing the appropriate system for a specific application.